Our Professional Services

Precision paper conversion solutions tailored to your specific requirements

Sheeting / Slitting & Rewinding Services

High-performance machines designed for precision paper cutting and rewinding operations

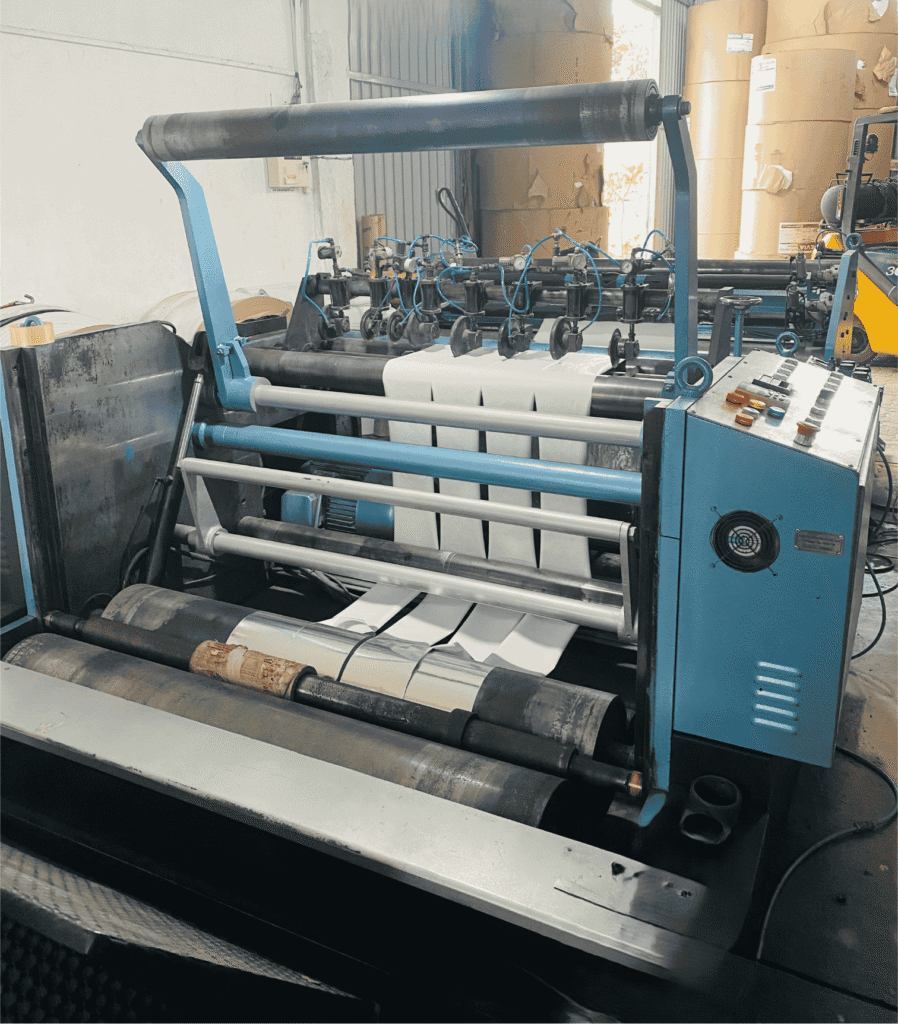

Slitting / Rewinding Services

Our advanced slitting and rewinding capabilities ensure precision cutting and efficient processing of various paper grades. With three specialized machines, we handle everything from delicate low GSM papers to heavy-duty board materials with exceptional quality and speed.

- SM 01 - Precision Light-Weight Handler

Specialized for lower GSM and smaller paper roll handling

Cutting capacity: 600 meters per minute

Perfect for delicate paper grades requiring precision handling

- SM 02 - Versatile Mid-Range Processor

Designed for middle grade paper slitting and rewinding

Cutting speed: 600 meters per minute

Additional capability to handle SM 01 workload for enhanced productivity

- SM 03 - Heavy-Duty Industrial Machine

Extraordinary heavy-duty capability for maximum weight handling

Weight capacity: Up to 2000 kg (2 MT)

Cutting speed: 400 meters per minute

Board handling: Up to 400 GSM (weight dependent)

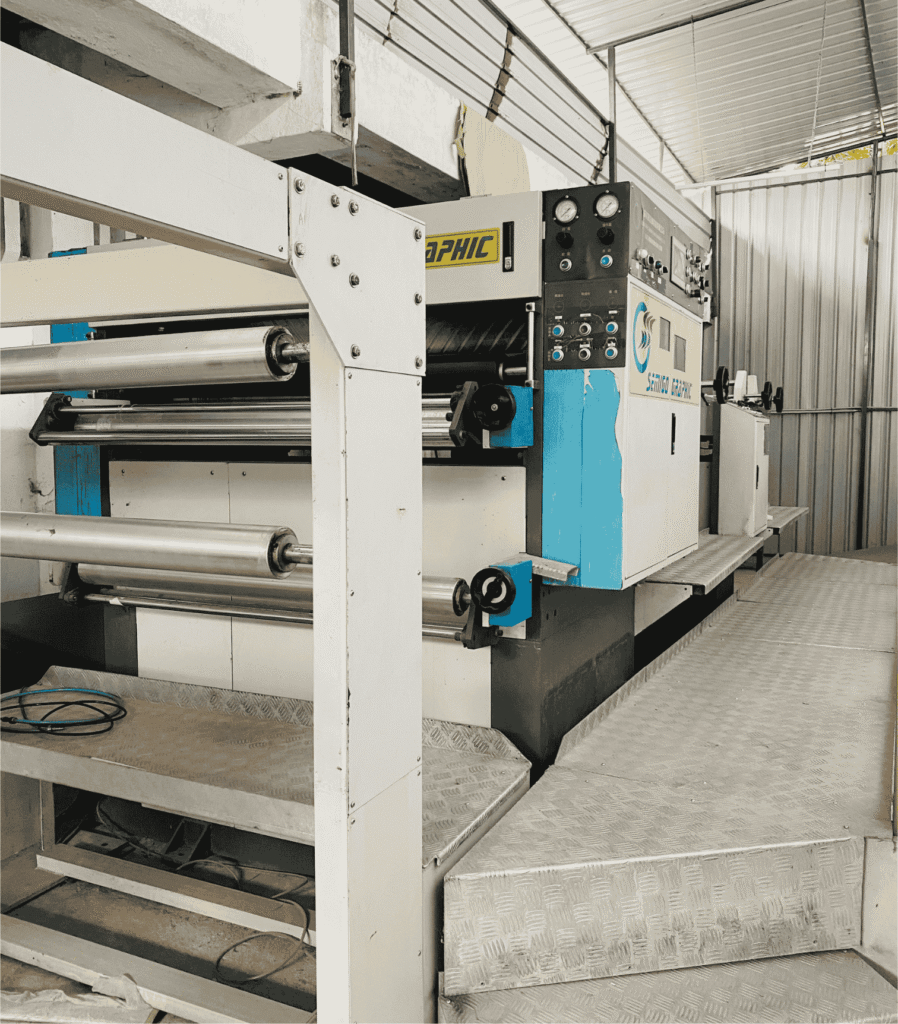

Paper Sheeting Services

Experience the future of paper cutting with our newly assembled AI-powered paper sheeter. This cutting-edge technology ensures precise, efficient, and consistent results across a wide range of paper specifications and formats.

- AI-Powered Paper Sheeter

Advanced AI Technology Integration:

• Paper range: 40 GSM to 400 GSM

• Cutting dimensions: 450mm to 1400mm

• Loading capacity: 1000kg (1 MT) per loading point

• Equipped with modern AI technology for optimal precision and efficiency

• Suitable for both lightweight papers and heavy board materials

- Key Benefits:

- Precision cutting with AI-guided accuracy

- Wide range of paper weight compatibility

- Flexible cutting dimensions for various requirements

- High-capacity loading for efficient production

- Modern technology ensuring consistent quality